Massman Automated Pleated Filter Assembly Equipment

Pleated Filter Assembly Automation

Massman Engineering is providing the pleated filter industry with a wide range of filter assembly automation solutions.

Look to Massman for a diverse offering of filter assembly equipment from semi-automatic to fully automatic models. These systems are capable of positioning the pleated block, forming the pleated material into a cylindrical shape, and securing the joint with a metal clip, hot melt adhesive, or an ultrasonic weld. Massman also offers turnkey filter assembly equipment that assembles the filter, center tube, canister, and end caps as a finished unit, all at rates up to 50 parts per minute (ppm).

Automatic Cartridge Assembly Machinery – ACAM

The Massman WB-ACAM is a fully-automatic filter cartridge assembly machine that is direct fed from either a rotary or blade pleater. This machine forms the cylindrical filter shape, can insert an optional center tube, it seams the first and last end pleats, and funnels the filter down to its specified outside diameter. The machine includes an automatic reject, has HMI assisted servo controlled changeovers and it cycles at speeds up to 30 to 60ppm depending upon seaming method.

Manual Cartridge Assembly Machinery – MCAM

The Massman MCAM-1300 is a semi-automatic, manual load, pleated media first and the last pleat seaming machine. It seams cellulose, synthetic or wire back media slit widths up to 13-inches (330mm), pleat heights greater than 1.5-inches (38mm) upon request, and media thickness greater than 0.125-inches (3.2mm). This is PLC controlled with HMI interfaced servos for automatic changeover adjustments within 20-seconds. The cycle speed is operator-dependent up to 30ppm.

End Cap Assembly Machinery – ECAM

The Massman ECAM can be purchased in either a semi-automatic manual load configuration or as a fully automatic assembly system with seamed cartridges loaded directly from a Massman seaming machine. End caps made of metal, plastic, moldable adhesive or felt in various shapes can be accommodated in diameters of 2 to 4 inches (50 to 100mm) with semi-standard machinery. Machines are PLC controlled and HMI interfaced with automatic servo changeovers where possible, often having 1-minute changeovers for dimensional variations. Cycle rates of 20, 30 and even 60 ppm are typical.

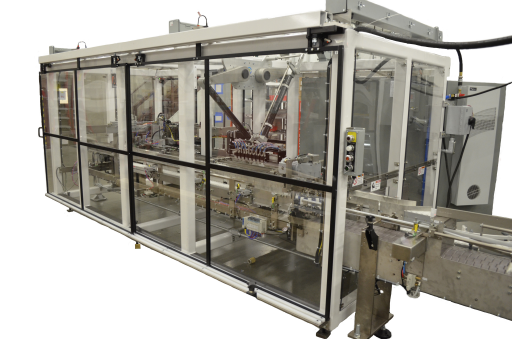

Robotic Assembly System (RAS) & Robotic Vision Assembly Systems (RVAS)

The Massman Robotic Assembly System (RAS) and Robotic Vision Assembly Systems (RVAS) are fully automatic robot systems that assemble filter components at speeds of 60, 90, and 120 ppm. Components such as filter cartridges, springs, check valves, grommets, o-rings, sensors, drain valves and nut plates have all been assembled using end effectors of various styles including expanding mandrels, vacuum or pneumatic grippers, electro or permanent magnets. The systems can be used in factory automation environments, clean rooms, and even booted for wash-down applications.

F-600 and F-1200 Forming Cartridge Assembly Machines (FCAM)

Massman Engineering engineers are experts at designing systems that help you increase cartridge production efficiency, improve production flexibility and reduce manufacturing costs.

The F-600 and F-1200 Cartridge Assembly Machines provide a low-cost, ergonomically friendly method of forming pleated filter media from a flat pleated block into a cylindrical shape for the assembly of oil filters, gas filters, water filters, and air filters.

Pleated Filters and Their Assembly

Automated machines like pleated filter assembly equipment construct products through a single streamlined process. These assembly methods involve the use of numerous automation system parts and components. To begin, an assembly line feeds the pieces into the robotic machine, which selects and moves each element into the assembly fixture before securing it into the appropriate position.

The assembly fixture then holds the part into place. At the same time, the robot shapes the pleated material into a roll and secures the adhesive joints using bonding technology ranging from welding and clipping to hot melt adhering. These bonded joints connect substrates of varying thicknesses, small-scale adherends, and homo- and heterogeneous substrate materials.

Applying the adhesive joints accomplishes several objectives:

- Minimize construction weight

- Create visually appealing connections

- Reduce the number of necessary joint fasteners

- Dampen vibrations

- Promote a uniform structure

- Distribute stress evenly

- Minimize joint assembly time

- Save on assembly costs

- Resist water, grease, oil, and corrosion

Types of Machines for Assembly Automation

At Massman, we carry over a dozen pleated filter assembly machines designed to fashion expertly pleated filters with optimal speed and precision. Within our comprehensive equipment selection, you can find two primary types of pleated filter machines.

Semi-Automatic

Semi-automatic filter assembly equipment uses machine-aided operation to function but still requires some degree of manual intervention. This manual effort may be as minimal as loading and unloading the system or as significant as conducting station checks to approve conveyor movement as it travels down the assembly line.

Semi-automatic pleated filter assemblies are typically used for low-volume production or applications where the component’s size, shape, or geometry prevents automated feed system usage.

Fully Automated

Fully automated filter assembly machines do not require any human interaction, meaning the system can handle all parts of the construction process on its own, from product loading and assembly to testing, inspection, and unloading. Other functions that fully automatic assembly equipment can perform include:

- Snapping

- Grabbing

- Bonding

- Sorting

- Screwing

- Tight-fitting

- Riveting

- Placing

- Welding

- Contacting

Massman Automated Filter Assembly Equipment

Our comprehensive inventory of pleated filter assembly solutions include:

- Forming Cartridge Assembly Machine (FCAM) – Former: Our F-600 and F-1200 Cartridge Assembly Machines create pleated filter media by using flat, pleated blocks and making them into cylindrical shapes. They’re ideal for gas, oil, water, and air filters.

- MCAM – Series H Hot Melt Adhesive – Seamer: Massman semi-automated pleated filter assembly equipment forms pleated materials into cylinders and secures them with hot melt adhesives at 5 to 30 parts per minute.

- MCAM – Series U Ultrasonic Weld – Seamer: Like our Series H seamers, our ultrasonic weld machines form cylinders from pleated media. However, they fasten the joints with an ultrasonic weld at 5 to 30 parts per minute.

- MCAM – Series C Metal Clipper: These machines use a metal clip to form pleated materials into cylindrical shapes at up to 30 parts per minute.

- Automatic Cartridge Assembly Machinery – Seamers: Our semi-automated seaming equipment joins pleated materials at speeds of 30 parts per minute.

- End Cap Assembly Machinery: The End Cap Assembly Machine automates filter assembly and handles a comprehensive array of filter sizes with quick changeovers.

- End of Cartridge Assembly Machine – Molded Formed: This machine uses mold-forming automation to handle pluriform, urethane, plastisol, and other proprietary formulas.

- ACAM – Series H Hot Melt Adhesive – Seamer: Our automated pleated filter equipment forms materials into cylinders and uses hot melt adhesives to secure the media joints at 45 to 60 parts per minute.

- ACAM – Series C Metal Clipper: The Series C Metal Clipper uses a metal clip to form and secure pleated media at 25 to 50 parts per minute.

- End of Cartridge Assembly Machine – Potted: This end cap assembly machine exercises filter assembly automation using various potting materials, such as hot melt, disk adhesives, plastisol, and epoxies.

- End of Cartridge Assembly Machine – Embedder: Our embedders automate filter assembly using remelt plastics and various heating methods to implant the filter into the end cap.

- End of Cartridge Assembly Machine – Ultrasonic Weld: Massman Ultrasonic Weld filter assembly equipment can work with any shape stamped online before the assembly process. It can weld paper media to end caps with high plastic content.

- ACAM – Series U Ultrasonic Weld – Seamer: This automated Series U seamer joins pleated media with ultrasonic welding at rates up to 30 parts per minute.

The Benefits of Automated Assembly

When you use automated filter assembly machines for your industrial facilities, you’ll experience all the following advantages:

- High manufacturing quality: Automated assembly systems are designed to perform detailed production tasks with repeatable methods and effective process integration, enabling them to achieve high-quality manufacturing results.

- Production consistency: Because robotic pleated filter assembly equipment detects errors throughout the production process, it minimizes variability and promotes a more consistent output.

- Labor minimization: Filter assembly machinery lowers labor costs by reducing the need for human intervention.

- Reliable processes: Because automation executes assembly processes precisely and repeatably, it makes products to the same specifications every time.

- Tracking capabilities: You can track and trace products as they move through the assembly line and quickly identify the source of any issues that arise throughout the process.

- Larger volumes: Using automated machines enables companies to achieve higher production rates, fulfilling greater demand.

Interested in Working With Massman?

If you’re looking to invest in automated filter assembly equipment designed to optimize your manufacturing processes, consider working with Massman. We’ve maintained our positive reputation in the packaging industry for over 40 years by developing standard and customized automation solutions for our customers while delivering exceptional customer service and responsiveness.

Request a consultation or call 320-554-3611 to get started with our team today!