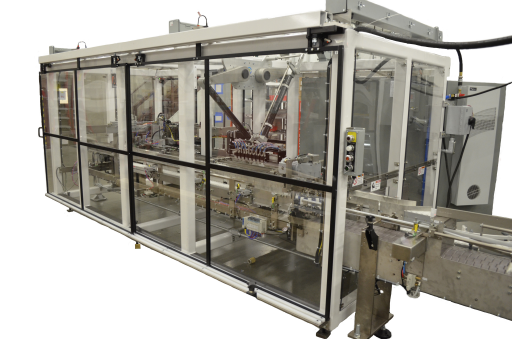

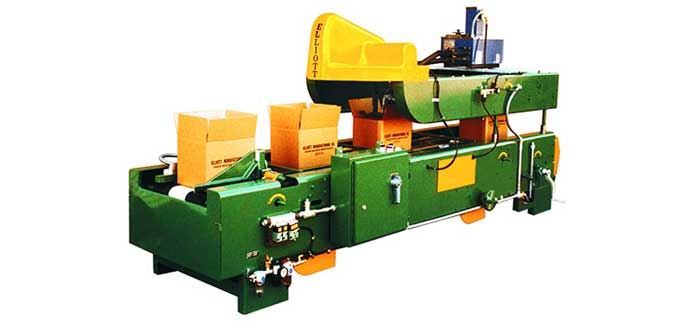

High Entry Palletizer Machine

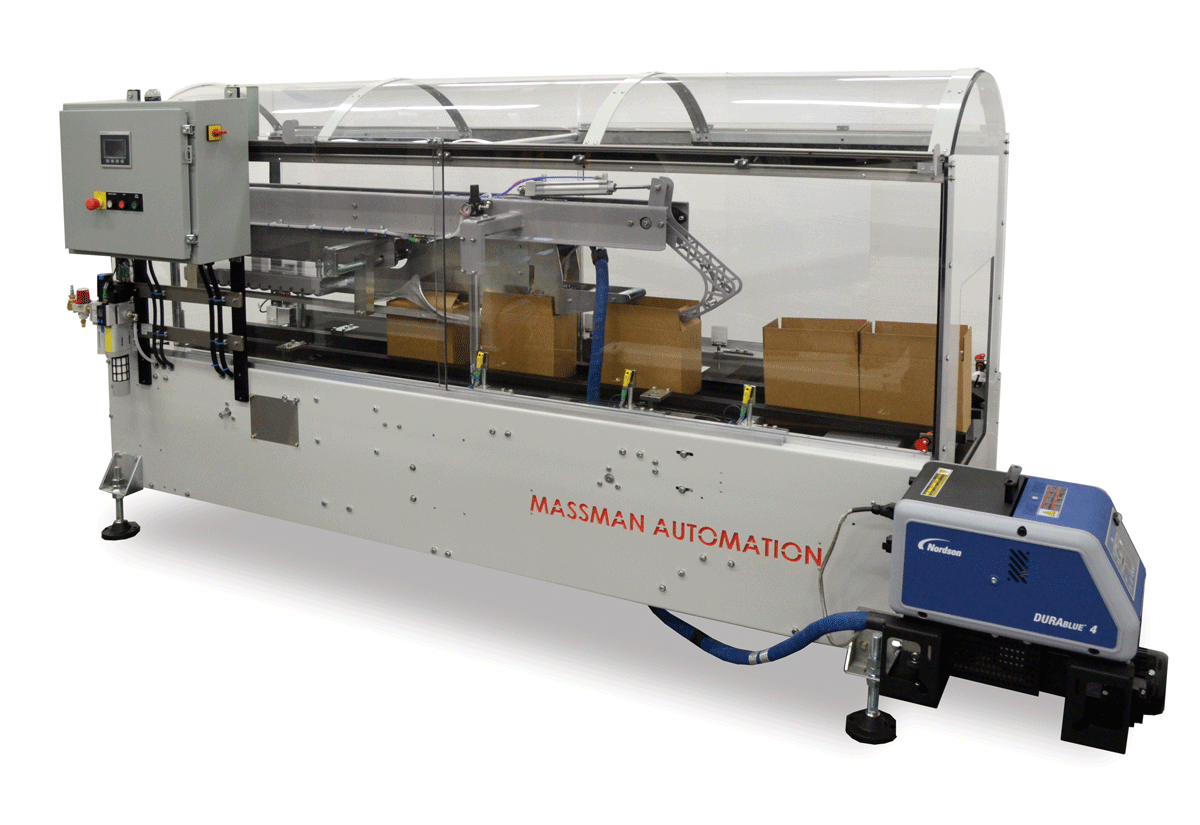

The Massman Automation high entry palletizer is a great solution for palletizing 40-pound cheese blocks for the dairy industry.

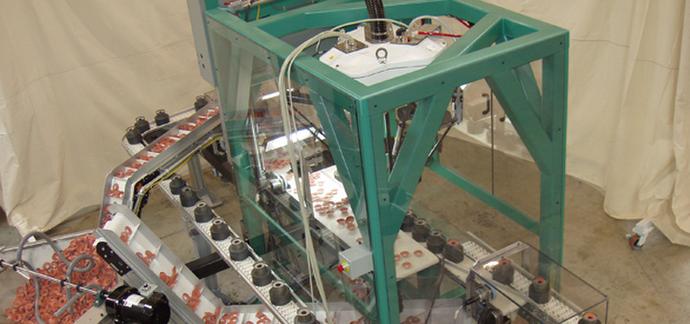

The high entry palletizer accepts a case, rotates the case if necessary for label viewing, and creates rows of cases to achieve the desired tier pattern (to provide a cooling chimney where necessary), places a layer sheet as required, then lowers the pallet for the next tier, and repeats this process until the pallet is completed and discharges via a powered pallet conveyor.

Incorporating both conventional and robotic palletizing technologies, this palletizer system ensures efficient and precise handling of cheese blocks while maintaining product integrity. With its advanced arm tooling and sophisticated row forming capabilities, the system can adapt to various packaging types and sizes. It offers a versatile solution for dairy processing facilities. From sorting and transferring to stacking and forming, enhancing overall productivity and efficiency.

GET A QUOTE ON A HIGH ENTRY PALLETIZING MACHINE

Learn More