Production Solutions By Machine

What Type of Machine Are You

Looking For?

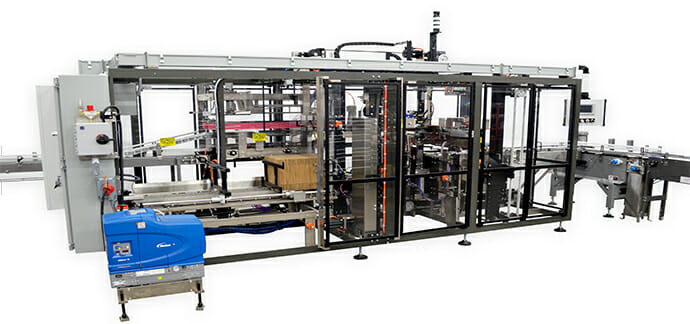

Case Packing

Massman Automation Bottom Load Case Packers are designed with safety, durability, productivity, and efficiency in mind as the top design criteria. In addition, bottom-load case packing provides for a more gentle treatment of products and handles products not pickable by vacuums. The bottom load case packer is designed to your specifications. These heavy-duty machines are built to be dependable under multi-shift conditions. With Massam Automation’s in-house technical expertise in the design and programming of this equipment, you can be assured of years of efficient productivity and low-cost ownership.

Cartoners

Massman Automation’s Ultra Cartoners delivers a cost-effective, innovative, and high-quality packaging solution. Cartoning is a versatile and cost-effective packaging method that can handle high volumes of products. Nearly every industry, from cosmetics to food and pharmaceuticals, uses cartoning because of its numerous benefits. Massman Cartoners can be paired with a Massman Case packer and Palletizer to create a full-line product line packaging solution.

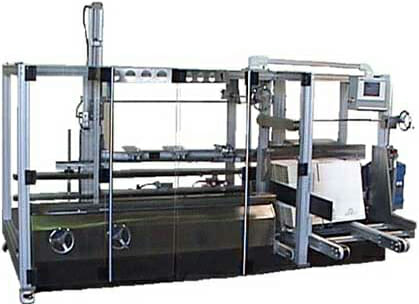

Case Erecting | Sealing

Massman Automation case erectors and case sealers are designed with safety, durability, productivity and efficiency as the top design criteria. In addition, the case erector and case sealers include all the features found in the standard Massman Automation case packer. The case erectors and case sealer are designed to your specifications. These heavy-duty machines are built to be dependable under multi-shift conditions. With Massman Automation’s in house technical expertise in the design and programming of this equipment, you can be assured of years of efficient productivity and low-cost ownership.

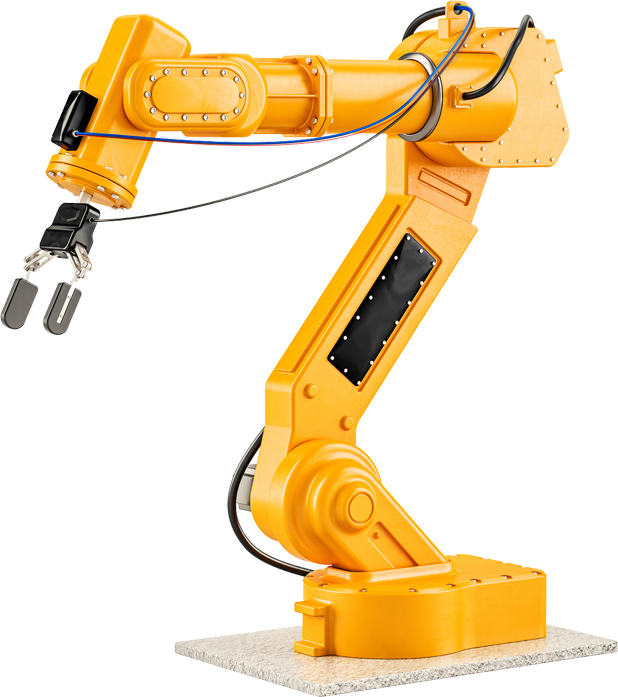

Palletizing Equipment and Systems

Massman Automation Designs has proudly been providing “end-of-line” packaging equipment solutions to a wide variety of industries for more than 40 years.

Massman Automation offers a small footprint, low-cost gantry palletizing solution, a high entry palletizing solution specifically designed for the handling of 40-pound cheese blocks, and robotic palletizing solutions capable of handling multiple packing lines.

See Our Machines In Action

Bottom Load Case Packer for Frozen Pizza Video

- Machines: case-packer

- Attributes: bottom-load

- Application: frozen-pizza

Continuous Motion Case Packer Video

- Machines: case-packer

- Attributes: continuous-motion

Stay Up To Date On Our Latest News & Events

Latest News & Events

Massman In The Media

Excerpt From Packaging World Magazine, June 2020:

Harvest Health Automates Cannabis Pouch Filling

“The resulting automated system, now operating at the Harvest facility in Flagstaff, Ariz., consists of an Eriez infeed conveyor and an Ishida multi head weighing system positioned on a mezzanine above a General Packer GP-M3000 automatic pouch filling and sealing system provided by Massman Automation Designs, General Packer’s exclusive distributor in the U.S.”