Case Packer Machines for Every Application

Case Packer Machines for Every Application

We have case packing solutions for every application, from small footprint, and low-speed applications to large high-speed continuous motion case packers. Our automatic case packers handle wraparound, RSC knockdown, harness style, and tray blanks. Below are all the different case packing solutions available to our customers.

We have case packing solutions for every application, from small footprint, and low-speed applications to large high-speed continuous motion case packers. Our automatic case packers handle wraparound, RSC knockdown, harness style, and tray blanks. Below are all the different case packing solutions available to our customers.

Massman also integrates several different types of robots of various sizes to automate product handling for a wide variety of industries. Massman Automation uses robots to accomplish complicated articulating motion, high-speed flex-picking applications, and continual heavy-lifting applications, such as palletizing. A vision system is added where required.

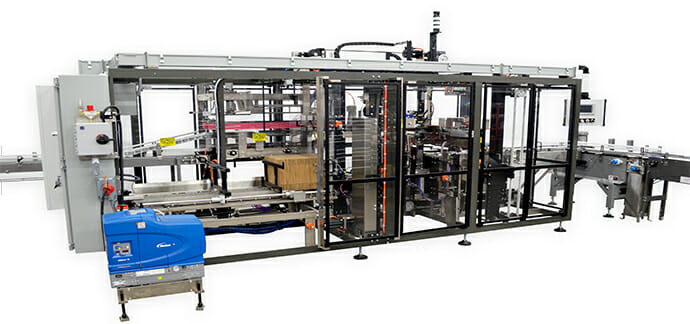

Bottom Load Case Packer Machine

The Bottom Load Case Packer while maintaining a vertical orientation of the RSC case, loads products from the bottom. This design ensures that your products are always fully supported, minimizing any damage or loss of product during the packing process.

If you’re looking for a versatile and efficient case packing solution, Massman Automation’s Bottom Load Case Packers offer a range of advantages:

- Our Bottom Load Case Packers provide gentle handling of your products, ensuring that they remain fully supported and minimizing the risk of damage or loss during the packing process.

- With our bottom load design, you can load flexible or complex products that may not be suitable for other packing methods.

- Our machines are capable of case forming, loading, and sealing all in a single process, streamlining your packing operation – saving valuable time and labor costs.

- This machine’s compact footprint is designed to maximize your floor space while still providing the packing capacity you need.

- Offers a choice of tape or glue closure options, giving you the flexibility to choose the best option for your specific products and application

Request A Quote On A Bottom Load Case Packer

Top Load Case Packer

The top load case packer loads product through the top of an RSC, wraparound, or harness style case.

Massman Automation incorporates its proven vacuum gantry pick-and-place robotic technology in conjunction with lowerator or escapement product handling.

Continuous Motion Case Packer Machinery

The continuous motion case packer loads the RSC case or wraparound case from the side.

Massman Automation incorporates its proven technology of product handling using servo motors. Product is collated and push-loaded through the end or side of the erected RSC or wraparound case blank.

Wrap Around Case Packer Machine

The Wrap Around Case Packer places product from the side or top of the wraparound, harness style, or tray blank.

Video: Wrap Around Case Packer Handles 8pk Cartons

Massman Automation is the industry leader in wraparound case packing. The benefits of wraparound case packing are numerous, such as flat blank storage and shipment and greater case blank magazine capacity. Typically, corrugate use is lowered and the cost per blank is less due to the unglued manufacturer’s joint. Improved palletizing can be achieved because the loaded Wrap Around cases are more square than a typical RSC type case.

Robotic Case Packer Machine

Robotic technology allows integration of all types and sizes of robots into our case packers to provide unique and special product handling.

Massman Automation has integrated ABB, Fanuc, and Motoman robotics into its case packers to handle challenging products for a wide variety of industries. From bagged products for the confectionery industry, and flexible pouches for the food industry, to gable-top containers for the dairy industry.

End/Side Load Case Packer

The Knock Down or KD case packer loads the product through the end or side of an RSC style case blank.

Massman Automation incorporates its proven technology of product handling using servo motors, Product is collated and push-loaded through the end or side of the erected RSC case blank.

Video: Side Load Case Packer: Paint Cans

Cheese Block Case Packer

The 40 pound cheese block case packer is a fully automatic case packer capable of up to 25 blocks per minute with the integration of the corrugated collar.

Massman Automation leads the industry with the 40 pound cheese block case packer. The machine has a proven track record of 24/7 production.

GET A QUOTE ON A CHEESE BLOCK CASE PACKER

Massman Automation cheese block case packers are designed with safety, durability, productivity and efficiency as the top design criteria. In addition, the wraparound cheese block case packer is capable of handling harness style case blanks, trays with or without display windows, and case blanks with tear-off perforations. The wraparound case packer is designed to your specifications. These heavy-duty machines are built to be dependable under multi-shift conditions.

The wraparound case packer for 40 pound blocks of cheese was designed with extreme durability in mind. Capable of running 24 hours a day, 7 days a week this case packer helps the customer to meet all of their production needs. With Massman Automation’s in-house technical expertise in the design and programming of this equipment, you can be assured of years of efficient productivity and low-cost ownership.

Advantages:

- Capable of speeds up to 25 blocks per minute

- Insert placement to protect product (optional)

- Servo driven loader/discharge rail system

- Ability to add and integrate robotic palletize to the end of the line

The Massman Companies provide many other solutions for the cheese and dairy industry, including but not limited to:

- Cheese Barrel Erecting with Add-on Lidder Machine

- Butter Case Packer

- Knock Down Case Packer for Cartons of Ice Cream

- Side Feed Single Tight Wrapping of Ice Cream from our EDL division

Learn more about the Massman Cheese Block Case Packer and read more on the case packaging and palletizing process, installation and integration, and results.

Cheese Block Case Packer Machine for Wisconsin Cheesemaker

Butter Case Packer Machines

Massman Automation offers a Butter Case Packer for Elgin or Western Style pounds of butter

Massman Automation Acquires EDL Packaging

Case Packing Equipment

Case packing machines improve the efficiency of your manufacturing process and increase your productivity. When you invest in automated case packing equipment, you’ll see a quick return on investment. Your staff will have the time to take care of other vital parts of the manufacturing process.

The case packing process begins when you place a layer of film over the products of pallets that need transporting. Depending on the package, you may require a simple layer of film, a layer of film and tray, a layer of film and padding, or complete wrapping around your items. After you’ve packed your cases, they’re ready for transportation and hitting shelves.

Automated Case Packing Machine From Massman Automation

Massman Automation specializes in creating the following case packers:

- Bottom load case packer: We offer bottom load case packers that gently load products from the bottom to ensure the integrity of your products. These case packers come with a small footprint and are ideal for products that require delicate packaging and handling.

- Top load case packer: Our top load packers provide a faster means of effectively packaging your goods. Massman top load packers use a vacuum gantry pick-and-place technology to provide reliable product handling.

- End/side load case packer: End/side load case packers — or Knock Down packers — load products through the end of a blank RSC-style case. At Massman Automation, our Knock Down packers use servo motors to push products through for an efficient and fast packaging operation. Our end/size load case packers are built to work under multi-shift conditions. We also offer continuous motion end/side load case packers.

- Wraparound case packer: As the industry leader in wraparound case packers, Massman produces side and top loading case packers that lead to a lower cost per blank. Our wraparound case packers allow for greater blank magazine capacity and lower cost per blank.

The Benefits of Case Packing Automation

Automated case packing provides businesses with versatile equipment ready to take on various product lines. Case packing machines bring the following benefits to improve your ROI and improve your operations:

- Large size ranges: Automated case packers have excellent size ranges, packing even large products with ease. This capability allows you to quickly accommodate a wide variety of products, including those in display-case and shelf-ready configurations.

- Various speed rates: You can customize Massman automated case packers to work at slower speeds for delicate packaging and faster speeds for more rugged products.

- Versatility: Automated case packers allow you to run multiple designs through the same machine. We custom-design our automation solutions for your products, which you can further optimize and upgrade to accommodate new sizes, speeds, and designs.

Interested in Working With Massman?

Massman Automation has been perfecting our case packing automation for more than 40 years. We have the experience necessary to build you a custom case packing machine for any product. Our team is ready to rise to the challenge of your end-of-line process. To learn more about our automation solutions, request a consultation or call us at (320) 554-3611.